Environmental Management

Environmental Policy

- The Sunstar Group acknowledges sustainability ideas and action are vital for business value and will continue to contribute to the formation of a society that develops sustainably.

- The Sunstar Group will unite to reduce its environmental footprint primarily through sustainable packaging, product development and resource selection, and energy usage plans with an aim to become carbon neutral.

- The Sunstar Group will leverage its global network to learn about pioneering environmental technologies related to materials and processing and actively apply them within supply and value chains.

8 Action Guidelines

- We recognize the importance of global environmental issues and conduct business activities in harmony with the natural environment.

- We will increase the efficiency of natural resource and energy use throughout the value chain of corporate activity.

- We will promote waste reduction, higher recycling ratios and use of renewable resources throughout the value chain of corporate activity.

- We will develop products, packaging and manufacturing processes that are friendly to the environment throughout the product lifecycle.

- We will supply safe and highly reliable products to markets around the world in compliance with environment-related laws, agreements and conventions.

- We will endeavor to make environmental policy and activities understood by all employees and strive for elevated awareness of the environment and knowledge of environmental issues.

- We will disclose initiatives and achievements in reducing our environmental footprint to markets to improve the level of our environmental controls.

- To minimize the negative impact of our business activities on the ecosystem, we aim to create a supply chain that preserves biodiversity and to implement voluntary community support.

Environmental Management Structure

We have appointed an executive officer in charge of sustainability in the Group Executive Committee and are promoting environmental management in the Consumer Business Group and the Industrial Business Group, respectively, in close coordination with each other. In addition, our major manufacturing sites conduct environmental management based on ISO 14001.

Environmental Management System ISO 14001

Major production sites of the Sunstar Group have received ISO 14001 certification.

Mid- to Long-Term Environmental Targets

In light of recent international efforts to tackle global environmental issues, such as the Paris Agreement, Sustainable Development Goals (SDGs), and the setting of carbon neutral goals by various governments, the Sunstar Group established a set of Mid-to Long-Term Environmental Targets for global operations at the end of 2020. The entire Group, encompassing both consumer and industrial businesses, is now working together worldwide toward attainment of these targets.

In particular, we will focus on striving for carbon neutrality by 2050 across our manufacturing and working facilities. To do so, we will seek to reduce CO₂ emissions by adopting renewable energy and streamlining activities and undertake proper management and reduction of water usage measures.

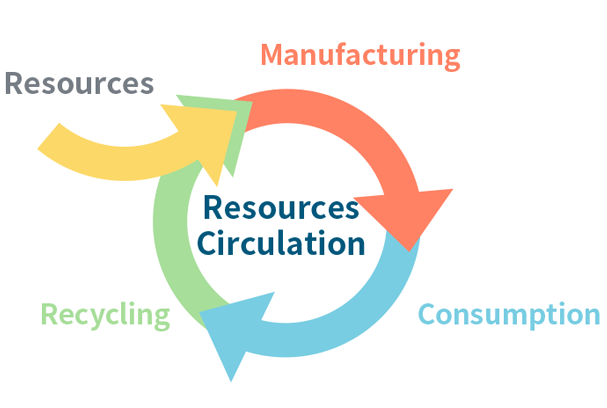

In product and packaging development, we will contribute to resource circulation (circular economy) by reducing consumption of petroleum-based raw materials and purchasing materials that preserve biodiversity. We will particularly focus on reducing the environmental impact of packaging materials by switching to plant-based and recycled plastic.

Towards carbon neutrality

We commit to reducing greenhouse gas emissions and achieving carbon neutrality by using renewable electricity and solar power across our facilities.

Towards circular economy

For plastics used in products, containers, and packaging, we contribute to resource circulation (circular economy) by utilizing renewable materials and facilitating recyclable product design.

Mid- to Long-Term Environmental Targets and Results

Plastics for containers and packaging:

Increase ratio of plant-based/recycled plastics used*1*2

| Results and Evaluation | |

| 2022 Achievement | 6% |

| 2023 Achievement | 14% |

| 2023 Evaluation | ○ |

| 2023 Summary and Next Steps | In addition to the use of recycled plastic for packaging of toothbrushes and interdental brushes, we have increased this ratio by switching to plant-based plastic for mouthwash bottles from 2023. This packaging uses the largest amount of plastic out of all Sunstar's packaging materials. We will expand to other product lines and reduce the use of petroleum-based virgin plastic. |

Post-consumer packages and containers:

Increase ratio of recyclable or reusable material used*1*2*3

| Results and Evaluation | |

| 2022 Achievement | 68% |

| 2023 Achievement | 75% |

| 2023 Evaluation | ◎ |

| 2023 Summary and Next Steps | We have achieved excellent results in relation to metal cans for adhesives and sealants. On the other hand, many containers used in the Consumer Business are made of composite materials to ensure quality and safety. Going forward, we will focus on developing containers that are easy to separate out at the time of disposal, while ensuring quality. |

Paper for containers and packaging:

Increase ratio of FSC®-certified or other certified paper used*1*4*5

| Results and Evaluation | |

| 2022 Achievement | 70% |

| 2023 Achievement | 71% |

| 2023 Evaluation | △ |

| 2023 Summary and Next Steps | We are progressively switching to FSC®-certified paper for packaging boxes and toothbrush/interdental brush package backings. The switchover in Japan is almost complete. We will continue to actively adopt FSC®-certified at a global level. |

Palm oil for products:

Increase ratio of RSPO-certified or other certified sustainable palm oil*6*7

| Results and Evaluation | |

| 2022 Achievement | 14% |

| 2023 Achievement | 25% |

| 2023 Evaluation | △ |

| 2023 Summary and Next Steps | In 2021, we joined the RSPO and started purchasing RSPO-certified palm oil for use in glycerine, the raw material for mouthwash. We are working to increase the rate of adoption of RSPO-certified palm oil and expand the product areas covered. |

Electricity used in own plants and offices:

Increase ratio of renewable (CO2-free) electricity*8

| Results and Evaluation | |

| 2022 Achievement | 27% |

| 2023 Achievement | 24% |

| 2023 Evaluation | × |

| 2023 Summary and Next Steps | The main oral care plant in Europe, located in Germany, the Global Group Headquarters in Switzerland are running on 100% renewable electricity. In addition to the main oral care manufacturing sites in Germany and Japan, new solar panels have been installed at our European Industrial Business site in Germany and our adhesives and metal parts plant in Singapore in 2023. There has, however, been a group-wide setback due to an increase in the number of locations for which we calculate data and a worsening electricity procurement situation. |

Water used in own plants:

Reduction of water consumption per production volume (per kg)*9*10

| Results and Evaluation | |

| 2022 Achievement | 9% |

| 2023 Achievement | -23% |

| 2023 Evaluation | ◎ |

| 2023 Summary and Next Steps | While there have been positive results in reducing water consumption thanks to an optimization in production processes, there has also been an increase in water consumption due to global warming. We will further analyse actual water usage and promote measures to reduce it. |

CO2 emissions from own plants:

Reduction of total emission (Scope 1+2)*8*9

| Results and Evaluation | |

| 2022 Achievement | -21% |

| 2023 Achievement | -13% |

| 2023 Evaluation | × |

| 2023 Summary and Next Steps | CO₂ emissions have increased since last year due to a lower renewable electricity procurement rates, an increase in the number of locations for which we are collecting data and a re-assessment of emissions intensity. We will continue to reduce CO₂ emissions by increasing the ratio of renewable electricity, installing energy-saving equipment and operating plant facilities more efficiently. |

* Scope of data:Data from group-owned global plants is integrated. Electricity, water and CO₂ are counted for the US Oral care plant, and electricity and CO₂ are counted for Tsubamex

Consumer Business = Oral care products, cosmetics, health foods, and other consumer product-related businesses

Industrial Business = Adhesives and sealants for automobiles, construction and electronics, and metal parts for motorcycles and automobiles

* Evaluation criteria: ◎ = Exceeds targets, ○ = Mostly on target, △ = Missed target but making progress, × = Worse than before

*1 Includes European procurement for consumer business

*2 Product containers and primary packaging materials (excluding subcontracted products for Japanese consumer goods and industrial goods)

*3 Recyclable or reusable material = Easily separable by material after product use

*4 Primary packaging materials (Excluding materials procured by subcontractors for Japanese consumer goods and industrial goods)

*5 FSC®(Forest Stewardship Council®)

*6 RSPO(Roundtable on Sustainable Palm Oil) For more on our RSPO Membership Progress, see https://rspo.org/members/12085

*7 In-house procurement, mass-balance products

*8 Including US oral care plants and our offices in Japan, Americas and Europe

*9 Base year: 2020 for the Consumer Business, 2019 for the Industrial Business (because 2020 was a year of significant production cuts for the client companies)

*10 Excludes groundwater from the Yamanashi Plant and the Industrial Business

List of “Mid- to Long-Term Target and Results” (PDF)